Autoelectro: Don’t fall foul to ‘part swapping’

Autoelectro, a prominent remanufacturer with nearly four decades of experience, underlines the necessity of technical proficiency amidst the surge in sophisticated vehicle components. In an era dominated by innovation, the rotating electrics specialist stands as an advocate for education and proactive problem-solving.

Despite Autoelectro still selling dynamos, inertia starter motors and ACR alternators, both the sector and the professionals it services find themselves amidst a technological revolution where electronic control units (ECUs) direct water-cooled, reversible alternators, stop/start systems, hybrid configurations, and a plethora of advanced starters, including tandem and dual solenoid varieties.

This change in direction requires a departure from the traditional approach of simply swapping out parts to address issues. Instead, the focus needs to shift towards understanding the intricacies of these modern components to diagnose and resolve the root causes of problems.

Autoelectro is approaching four decades and, therefore, recognises the significance of technical understanding in the current automotive landscape. It is particularly concerned about switches from quality remanufactured parts towards mass-produced alternatives from the Far East, forfeiting the technical expertise within the industry.

Not finding the underlying cause

For Autoelectro one of the core issues is the tendency to replace suspected faulty parts without delving into the underlying causes of the problem. This approach, addressing symptoms rather than causes, can lead to recurring issues and fails to provide a sustainable solution. It’s a short-term fix, not a long-term solution.

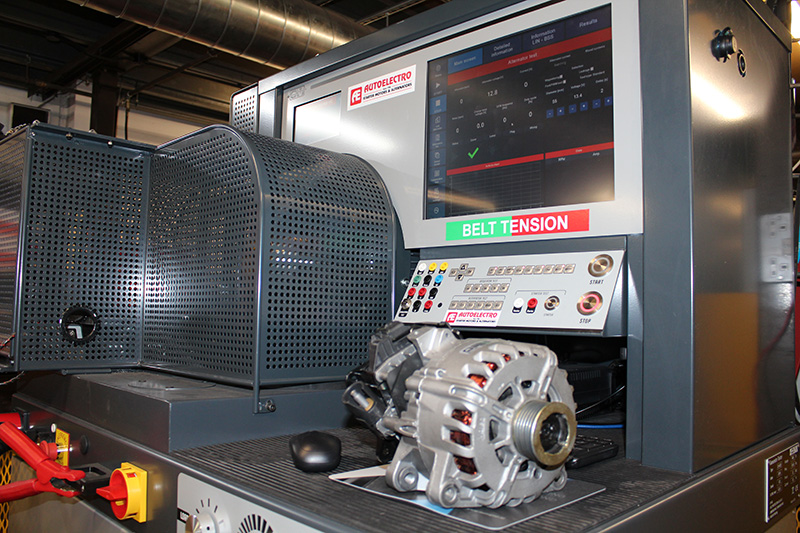

Autoelectro’s Harnek Bhogal, said: “Our commitment to technical excellence sets us apart. Unlike the trend of batch testing, every part released by us undergoes two rounds of testing – first at the component level and then as a complete unit on OE-spec test equipment. This meticulous testing process ensures that our parts meet the highest standards before reaching the market.”

Harnek also highlighted Autoelectro’s engineers; they play a crucial role in this process. By working with old cores and identifying common themes among specific part numbers, Autoelectro’s ability to strip, inspect and test exchange parts gets straight to the root causes of recurring faults. This proactive approach allows the company to go beyond merely supplying parts, offering invaluable insights into potential issues associated with specific engines or vehicle makes and models, remanufacturing a part to meet, or even exceed, OE-specification.

Collaboration between motor factors and technicians “critical”

Furthermore, Autoelectro believes the importance of collaboration between motor factors and technicians is critical. Blindly swapping parts without addressing the true problem could lead to an erosion of trust between garages and factors.

Harnek added: “We recognise this challenge and actively support garage technicians by providing part-specific technical bulletins. These offer guidance on common faults, best practices, and key indicators to look for in the old cores they remove from vehicles.”

One such example is if a pattern emerges where every returned old core is contaminated with fluid: Autoelectro issues a technical bulletin advising technicians to investigate and correct leaks before installing replacement parts; in fact, below are two examples of Autoelectro using its ability of testing, stripping down and investigating old cores to find common issues:

AEG1472 (Ford Transit 2.0 diesel alternator (2016-onwards)): possible tensioning or belt issue that causes premature failure of the clutch pulley and, thus, the premature failure of the alternator. Autoelectro recommends changing the belt and tensioner at the same time as replacing the alternator to avoid the same pulley issue happening again. Failing to do so may lead to the same fault occurring on replacement parts.

AEY2803 (Chevrolet Captiva and Cruze/Vauxhall Antara 2.0-2.2 diesel starter motor (2011-2016)): a common fault where the wiring insulation on the vehicle is not correctly heat shrunk, which causes the B+ terminal on the solenoid to overheat and melt, leading to the premature failure of the starter motor. Therefore, inside every AEY2803 box supplied, Autoelectro provides a warning notice, advising the technician and showing images of what damage to the solenoid and terminals looks like, to avoid the same issue happening again.

Harnek said: “Both of the faults on these part numbers can often be intermittent due to the nature of them; the tensioning issue, for instance, may cause the belt to slip, which can cause sporadic charging faults, while the incorrectly heat shrunk wiring insulation may cause intermittent starting issues on the vehicle, which will get worse over time.

“It is easy to see how a technician may think this is just due to wear and tear on the unit, when in reality, that is not the case, and the root cause must be fixed.”

By sharing these types of insights into common issues, as well as the likes of belt slippage or dust/fluid contamination, Autoelectro allows technicians to diagnose and rectify problems at the source.