Understanding iStARS Units

For more than three and a half decades, Autoelectro says it has amassed knowledge and experience that has allowed its team of experts to produce and supply a wide range of rotating electrical components. Autoelectro has embraced changes in technology, too, which have been integrated into its environmentally-friendly formula of re-engineering units from existing ‘core’ and returning it to its original condition and performance – at times, even exceeding it.

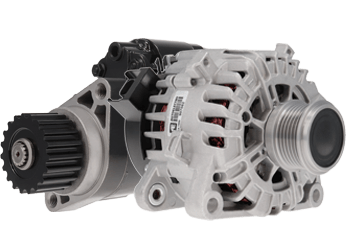

One of these shifts in technology has been the introduction of the Integrated Starter Alternator Reversible System – or iStARS.

Basic understanding of the iStARS

Stop-start technology and Integrated Starter Alternator Reversible Systems help reduce vehicle emissions and make economic differences for the driver, which should result in them making fewer trips to the fuel pump. Fuel savings of up to 3% and 15% are made when driving normally or stuck in traffic respectively. The iStARS solution is a reversible Alternator, which replaces the conventional Alternator and Starter Motor – to provide the combined function of the two components. The design allows the conversion of electrical energy into mechanical energy – and vice-versa. Later applications of conventional Alternators would have their charge rate controlled by the vehicle’s ECU; whereas, the iStARS has its own ECU which controls the reversible Alternator.

How does the iStARS work?

When the ignition key is turned, the vehicle’s ECU will start the engine. This is achieved by the battery providing the required electrical energy; the reversible Alternator then acts as a Starter Motor and starts the engine via an auxiliary belt. During normal driving conditions, the reversible Alternator behaves as a conventional Alternator by converting the mechanical energy into electrical energy and charging the battery. Once the vehicle’s speed has fallen below 5mph, and providing the gearbox is in neutral and the clutch pedal is released, the iStARS’ own ECU will command the engine to stop. Once the clutch is pressed and first gear engaged, the iStARS’ ECU sends another order to the engine to start again. When the vehicle is switched off by turning the ignition, the vehicle’s ECU will stop the engine. Tony Bhogal, Managing Director at Autoelectro Ltd, said: “We need support from workshops and motor factors, in particular, as, while they are entitled and correct to manage their profit margins, the evolution in vehicle technology and challenges technicians face in diagnosing and resolving issues, means they should be selling and fitting the best products possible – not bow down to price.

iStARS ‘proving popular’

The iStARS has been incorporated on many vehicle applications since its inception, such as:

• Citroën C4 diesel (2010-onwards);

• Peugeot 308 diesel (2011-onwards);

• Mercedes A and B-Class petrol (2005-onwards);

• Smart Fortwo petrol (2008-onwards).

UK Sales Manager, Nick Hood, commented that Autoelectro has established a range of reversible Alternators for vehicles, such as those identified above. He said: “Being based in the UK and owning our own remanufacturing facilities, allows us to supply a full range for the UK market.”